Zinc plating – yellow passivation

The yellow passivation based on trivalent chromium meets requirements of ReHS Directive.

The most important advantage of the process is corrosion resistance - the resistance to the white corrosion in salt spray chamber is 264 hours, and to the red corrosion 312 hours accordingly.

Zinc plating is carried out in the following manner:

- small parts – in a galvanizing drum

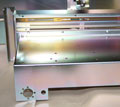

- hooked up parts to fit working section of frame (2100 x 600 x 1300)

- in special cases parts over 2500 mm long can be handled

The zinc plating with yellow passivation is performed on a fully-automated line which provides for repeatability of coat parameters. The process itself takes place in alkaline bath featuring perfect throwing power and very uniform thickness of metal coat which cannot be achieved in case of acid electrolytes.

The quality of coat can be tested in salt spray chamber on your request.

The price depends on order specification (coat thickness, parent metal quality, shape of parts, lot size).

Additional links